High Tech in Thailand: Touring Sony’s massive camera and lens production factory

posted Monday, April 10, 2017 at 12:15 PM EST

In early March of this year (that's 2017, for those of you reading this in the future), I and a small group of other members of the photo press had the opportunity to tour Sony's massive camera and lens production facility in Chonburi, Thailand. It's an impressive place. The photos and color commentary below tell some of the story of how Sony turns out so many cameras and lenses every day, and yet still manages to keep a tight grip on quality control to ensure each product off the line meets its standards. Without any further ado, here's my tour "diary".

As always, we received a warm welcome at the entrance, this time displayed on a TV. (Sony, of course.) The official name for the operating division we were visiting is Sony Technology (Thailand) Co., Ltd., and the factory is located in the Chonburi area of Thailand, approximately 60-90 minutes drive outside of Bangkok.

The first step (literally) in touring any Japanese company's factory is to exchange your street shoes for slippers. Similar etiquette applies in Japanese homes, too; you don't wear your street shoes into a house. It actually makes a lot of sense: Where does the dirt on your floors come from? Most of it is tracked in from outside. There's much less to clean, if you don't track it in in the first place :-)

The Royal Family -- and especially the recently-deceased King Bhumibol Adulyadej -- are greatly revered in Thai society, and the country is still in a year-long period of mourning after his passing on October 13, 2016. You'll find heartfelt tributes to him appearing as overlays on many websites, displayed in corporate headquarters, and so on. Shown at left above, this is him in much earlier years; as a keen photography enthusiast himself, he was often to be seen with camera in hand. His wife Queen Sirikit is on the right, and former crown prince and current King Maha Vajiralongkorn Bodindradebayavarangkun is shown at center. These portraits were directly above the welcome screen shown above, in the factory lobby.

The Chonburi factory grounds were quite parklike in areas. This little space was on the way between the morning's meeting room and the cafeteria. Being early March, it was technically early Spring there, which meant the temperature was a balmy 91F, with 70-80% humidity. Thai friends tell me that you really don't want to go to Thailand in April or May, when temperatures hit 100+ many days in a row. Having just flown in from a chilly, rainy Tokyo immediately before this, it was a bit of a shock. Not nearly as much, though, as it was for those who came straight from New York or Calgary!

After 90 minutes or so of greetings, briefings about the factory and Sony Digital Imaging's profits and market share (they're absolutely dominating the mirrorless market now, and fighting tooth and nail with Nikon for the second place slot in the mid- to upper-range ILC camera market), we went to lunch. In common with other meals we had in Thailand, there were lots of fresh vegetables. With the aforementioned winter temperatures in the 90's (Fahrenheit), they have farm-fresh vegetables year-round.

Here's some of our group, mingling with the Sony employees as lunch was getting started. Note the light blue vests everyone is wearing. It seems to be a popular practice for Japanese companies to give factory visitors a company vest or jacket to wear while they're there. It's not quite a uniform; workers and executives alike still wear their own choice of street clothes, but everyone in the factory has a company jacket or vest on top. (I saw the same thing in Canon's Utsunomiya, Japan lens factory when I toured it recently.)

The first stop on our tour (and the only part in which we were allowed to take photos) was the camera assembly area. A display case in the corridor outside showed all the camera models that are currently being produced there. Can you spot your favorite?

The first portion of the production line was devoted to subassembly production; all the various bits and pieces that go into making up the final camera. I think the worker on the left is working on hot shoe subassemblies, while it looks like the one on the right is doing some sort of internal sub-chassis assembly. (The black plates in the tray to her left are so big that they must be the internal frame itself.)

Electric screwdrivers are an absolutely ubiquitous tool in the factory workstations, suspended on retractable cords to reduce worker fatigue and get them out of the way when they're not actively being used. New worker training was one of the areas we weren't allowed to photograph, but I found it interesting that the first task people trained on was grabbing and inserting screws into metal blocks with hundreds of threaded holes in them. It's clearly one of the most basic tasks at the factory, so everyone needs to be good at it. About 30% of prospective workers are weeded out at that stage, if they can't achieve the speed and accuracy needed. (If they don't pass after the first go-round, they're given another chance, but if they can't meet production-level speeds after that, they're very regretfully shown the door.)

This worker is assembling components into the top of a camera body; you can see a little bin of neckstrap attachments in the middle left. The worker is just reaching for her screwdriver here. Those things with plexiglass covers with slots in them in the middle of the frame are automated screw dispensers. They have a V-shaped front that guides the screwdriver right to the screwhead, and feed one screw at a time from a bulk hopper on the back. I've often wondered how much these things cost; I'll bet they're at least a couple thousand $USD apiece, but they greatly speed the production process, and keep working shift after shift, 24 hours a day.

This worker is mainly assembling circuit boards into the bodies, but also doing something involving the front of the camera body. I think the lighted box to her right is a test fixture, with a body face-down inside it, the circuit board exposed on the back/top. If you look closely, you can see all the little flex-circuit connections sticking out of the camera body, waiting to be attached to the circuit board. Learning how to insert flex-circuits into connectors was an important part of new worker training.

Also note the barcode labels. We learned during one of the morning presentations that Sony tracks the identity of essentially every part that goes into every camera body. That way, if they encounter a problem, they can quickly trace it to its source, all the way back to the fabrication of the original components, circuit board part-stuffing and soldering, etc. This information is permanently recorded in their database, allowing them to track down possible problem causes, even after the cameras go out into the field and are sold to customers. When cameras require service under warranty, issues can be tracked back through the entire manufacturing history of each particular unit.

Sony devoted a significant amount of their morning presentation time to their (exhaustive) quality-control process. While the presentation was a little technical and they didn't let us take pictures of the slides they showed, it was extremely impressive. There are QC checks at every step of the production process, with feedback loops to correct and adjust for any drift in tolerances or increase in rejects. With the entire history of checks and adjustments in every phase of the production process, and the full production history of every camera produced stored within it, Sony's product QC database must be staggeringly huge.

While the aim is to eliminate problems before products make it out to end-users, if any problem does surface down the road, Sony can trace back and determine exactly which serial numbers might be affected. (See the entry below about writing serial numbers into the cameras; I was surprised to learn that it's not a matter of just incrementing a counter as units roll off the line.)

This worker is responsible for plugging all the flex-connectors into the sockets on the processor board. Counting what look like a couple plugged into the other side of the circuit board, I think she's already connected 9 circuits, with two more sticking out of the top control panel near her right hand yet to go. I'm glad it's her doing this not me; the process seems incredibly fiddly, done with tweezers and a good bit of dexterity. If I had to do this for an hour, I'd be climbing the walls; this lady does it for 8 hours/day (plus overtime shifts as needed).

This worker is doing an initial functional test, just after the firmware has been written to the camera bodies. You can see the firmware-writing station behind her. Writing firmware apparently takes a little time; judging from the display screens, it looks like that worker is writing firmware into 24 bodies at any given time.

Here cameras are going through another set of functional tests. In the full-size original of this image, the legend "GC-Common_Audio" appears on the leftmost screen above. There seemed to be quite a few testing stations, suggesting that testing took as long as quite a few of the manual assembly processes.

It may have been obvious in this and other shots, but it's worth noting that the production line snaked back and forth quite a bit. We were walking down along one side of it, but it was a good 20-30 feet "deep" at any given point, with aisles branching down into that depth from the main thoroughfare we were walking along. The detailed process flow wasn't clear, but it seemed to snake in and out, sometimes running down the back side before coming out to the front again.

In retrospect, one thing that stands out in my mind is that everone was working; it makes sense, but I don't recall seeing anyone moving around to get parts or move cameras from one point to the next. Everything was in arms-reach the vast majority of the time. Given the varying amounts of time different operations take, it must have taken quite a bit of planning and fine-tuning to arrive at the functional layout they ended up with, so everything could proceed smoothly at the same overall pace.

This step was interesting; the long black boxes are apparently something like mini-optical ranges, where the cameras' autofocus systems are calibrated. Lenses are attached to the cameras, and they shoot images of some sort of targets inside the boxes, presumably at different focal distances. I didn't have a chance to ask, but it's interesting to me that you'd need to calibrate an on-sensor phase detect AF system. One of the big advantages of on-chip PDAF is that it can't go out of adjustment, because the image sensor and phase-detect sensor are one and the same. I guess there must have to be some initial correlation between what the focus pixels see vs what's actually in perfect focus, as determined by contrast-detect AF based on the image pixels. Whatever is involved, it happens in these big black boxes, with the help of the associated computers.

(I have no idea what the "Process: ADD CHECK: MANUAL WATER LEVEL" sign in the background could be referring to. Water level? Whatever it is, it must be pretty important, as it was one of the biggest signs on the production floor, and had a photo of what I assume was the person responsible for it in the corner of one of the sheets tacked to it. "Dang it, the water level wasn't checked! Where's Fred? Get him out here!" ;-)

Here, the largely-completed camera bodies are being checked for basic operation with a lens attached. This seemed to be purely visual, with the cameras handheld, and no computer analysis of the images involved. I"m guessing it was just to check that everything worked properly when a lens was attached: It focused properly, the aperture worked, etc., etc. Here again, though the number of workers gives some idea of how long the process might take. Since there are three women here (I'm not sure, there might have been a fourth out of the frame to the right), it seems that whatever they're doing must take a little while, since it takes three or four of them to keep up with the rest of the line.

(There's a lot of speculation on my part about what's happening in different areas, because there was a fair-sized group of us, and we were probably only in the actual camera-assembly portion of the factory for 15-20 minutes. So there wasn't much time or opportunity to ask the kind of minutely-detailed Dave-questions I really like to. Still, it was pretty interesting, and kind of fun to try to decode what's going on after the fact :-)

Remember when I mentioned serial numbers earlier, and how they weren't necessarily just a continuous sequence of numbers? Well, this is what that was about. Notice that the sign above the worker says "Destination S/N Write and Body Pack"? It turns out that there are different serial number series for different parts of the world. Among other things, this probably helps keep things sorted between so-called gray-market cameras (ones that are bought in one country but then resold or used in another) and official stock.

Based on orders, sales projections and delivery schedules for all the local operating companies around the world, the computer system tells this operator which country or market region each body is destined for. It then writes the appropriate serial number for its destination, and the worker packs it in a retail box appropriate for where it's going.

So one camera off the line might get a serial number and box destined for the US, the next one might be headed for France, and the one after that for Japan. Good thing they have computers to keep track of all that :-)

This is what was immediately to the right of the guy in the previous photo. As you might expect, different things go in the box, depending on where each camera will be shipped to. (Instruction manual language(s), software disc, warranty card, etc., etc.) All of those bits and pieces are in the bins and boxes on the racks which we're seeing the back sides of here. Following directions from the computer, the workers on the other side pick out and pack the specific items needed based on the camera's destination.

This is what's on the other side of the shot above; a double-row of workers picking items and stuffing boxes.

And finally, here's the end result: A full pallet of Sony A7R IIs waiting to be shipped. (It's interesting that the "unit package" seems to be two retail-packaged cameras to a box; I wonder what resulted in that particular decision, vs one, three or four?)

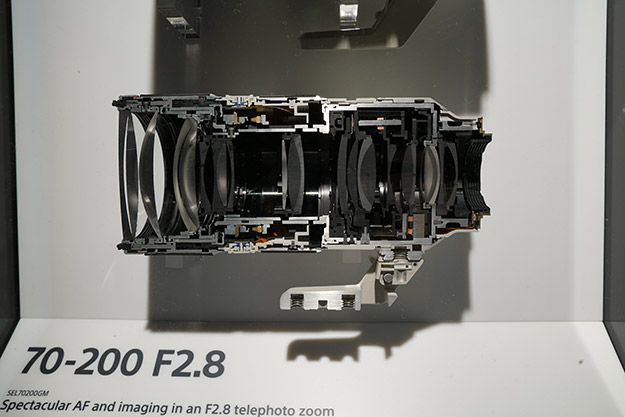

The Chonburi plant also produces all of Sony's FE-mount lenses. As was the case with the camera production area, these cases outside the lens assembly area held examples of the products produced. While we had a fairly extensive tour of the lens area, we weren't allowed to take photos inside it. (For a tour of a lens factory, see our recently-posted coverage of the first in-depth factory tour of Canon's Utsunomiya plant.)

Circuit-board assembly

The A7R II assembly line was the only area of the plant in which we were allowed to take pictures. That's a shame, because some of the other things were very interesting. One of my favorites was the circuit-board production line, which took in printed circuit boards (PCBs) and the zillions of little parts on them, and spit out fully assembled boards on the other side.

While we couldn't take photos, the steps in making a circuit board are pretty generic; we'll try to fill in some of the details with random illustration images from the web.

Cleaning and solder paste application

I lumped these together, because there wasn't much to explain about cleaning. (Although perhaps one interesting note: The entire assembly floor is a dust-free environment, so all the parts coming into it have to be washed before being allowed to enter. The level of attention to dust control was just crazy, in a good sense.)

The circuit boards all use so-called surface mount components, because they are, well, mounted on the surface of the PCB. The older alternative was through-hole mounting, where component leads were inserted into holes in the circuit board. Surface-mount is easier to automate, and also allows much higher packing densities on the boards.

The first step is to apply solder paste to the boards. This is a thick paste with microscopic balls of solder suspended in a solder-flux base. It's applied to the boards in a process that looks a lot like silk-screening, only instead of a screen, there's a metal stencil, with little holes in it everywhere the solder needs to go. The thickness of the stencil determines how much paste is left on the board. Too little and parts won't stick, too much and the solder will "bridge" between adjacent pads, shorting them together.

(Above image courtesy Indium Corporation.)

This is what it looks like when a stencil printer is laying down solder paste. There are blobs of paste on each side of the squeegee, so it can lay down paste in either direction. The viscous paste is squeezed down through the tiny holes in the stencil, the total amount that's deposited determined by the stencil thickness.

Computer-vision inspection

After every fabrication step, the boards are scanned by a high-resolution machine vision system to make sure that everything is to spec. The scan after solder paste application checks to see that the amount of solder on every pad on the board is just right. Too little or too much, or any solder bridging between pads, and the board is kicked off the line to be cleaned and re-used.

The precision and image processing power required here must be enormous. The circuit boards roughly matched the dimensions of the back of a camera, had thousands of solder pads on them, and some of the pads had to be on the order of one or two tenths of a millimeter or so on each side. - And the vision system needed enough resolution to be able to tell whether one of those tiny pads had too little or too much solder on it.

Pick-and-place

Assuming the solder paste was all in the right places and amounts, the next step is to load the boards with components. This is done by what are called Pick-and-Place (PnP) machines, for obvious reasons. Each PnP machine has rows of parts feeders along its sides, with either long tubes of parts plugged into them, or little components held on reels of plastic tape. The feeder gets each part ready to be picked up by the moving head, which then grabs it, moves to the right place on the board and puts it in position. The solder paste is made to be quite tacky, so it holds the parts in place until they can be soldered in the next step.

This is a different type of machine than Sony was using to mount components on their processor boards, but it gives you some idea of just how fast current pick & place technology is. (This one uses a rotary head, which was what we found when looking online for an example video of a really high-speed machine. The pick & place machine we saw in Sony's factory used rows of pickup heads. It could grab a dozen parts at a time from the feeders, so was faster at that portion of the process than a rotary-head machine, but there was more travel on the other end, to move the head between part placements.)

There were two PnP machines on the A7R II line, a slower one that handled the bigger components like integrated circuits, and a blindingly-fast one that dealt with all the small stuff. And I mean the second machine was seriously fast! When it was placing components, the arm moved so fast your eye literally couldn't follow it; it was just a blur sometimes. To further speed the process, the fast machine could pick up 12 parts at a time from the feeders, before moving to the board to place them. This cut down enormously on the time that would otherwise have been wasted, moving from the feeders to the board and back over and over again.

Computer-vision inspection

Not surprisingly, after the PnP machine is done the machine vision system checks the board to make sure that every part is in the right place (again, within placement tolerances of 0.1mm or less for some parts), that none are missing or skewed, and (I think) that the solder paste around the parts looks right.

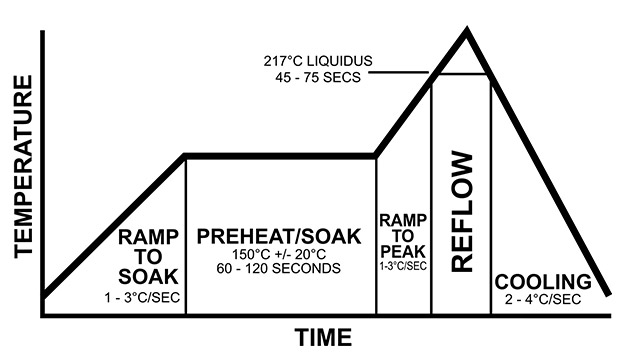

Reflow soldering

With all the parts and solder paste in place, the next step is to actually make the solder joints. This is done by passing the boards though a long tunnel-oven, with a precisely-controlled temperature profile like the one shown above. The boards have to be brought up to temperature at a controlled rate, to avoid thermal stresses, then "soak" for one to two minutes for temperatures to equalize between the different-sized parts, the board, etc. After that, the temperature is ramped up again, until the little balls of solder in the solder-paste melt and reflow around the parts and the pads on the board. After that, the temperature is ramped back down, at a few degrees per second, to avoid the thermal shock that would occur if they immediately encountered room-temperature air.

The reflow oven was a good 10 feet long, but electronic hobbyists can accomplish much the same thing with a toaster oven or even a hotplate.

There's not much to see on the outside of a reflow oven; it's just a long, boxy-looking machine. Inside, there are multiple heat zones, to precisely control the temperature as boards move through it on a conveyor system.

Machine-vision check

After the reflow process, yet another vision system checks that everything looks as it should. (Bet you didn't see that coming ;-)

Repeat and rinse

All of the above was to put components on just one side of the circuit board, and there are two sides. So the boards are flipped over, and go through the same sequence of operations to attach parts to the back side. (When the boards go into the second reflow oven, the solder on the underside of the board will obviously melt again. Fortunately, the surface tension of the liquid solder is enough to hold the previously-mounted parts in place, and keep them from falling off.)

The last step is a cleaning process that removes the leftover flux that was in the solder paste to make it wet well to the components and PCB pads, and makes sure the surfaces of the board are squeaky clean. Any surface contamination could result in problems down the road, after the boards had been in the field for a while.

As with pretty much everything else in the factory, the history of every circuit board (including sources and lot numbers of the components on it) is logged into the factory's master database. The amount of data stored there must be staggering.

Lens Assembly

We also saw a lens-assembly area that was off-limits for picture-taking. It was a lot like all the other lens assembly lines I've seen in the past. (Read about my extremely rare tour of Canon's Utsunomiya lens factory for details of one such facility, and my tour of Sigma's Aizu lens factory for a much more in-depth look.)

One thing I did notice that was different from the Canon or Sigma factories is that there were "clean rooms inside clean rooms" in Sony's plant. The entire lens assembly area was a clean room, with workers wearing "bunny suits" to keep dust from their clothing, hair dander, loose skin cells, etc from contaminating the production area. But in the Sony factory, there were special extra-extra-clean areas, walled off from the other sections with plastic curtains, suspended from the ceiling. The curtains extended to perhaps a foot from the floor, and there was a continuous flow of highly-filtered air from grilles in the ceiling downward, and into air-return registers at floor level. This way, any dust that might be kicked up anywhere would be swept down by the airflow, providing even higher levels of cleanliness than the "normal" clean room around it.

Worker Training

When we were there, Sony was just training a new set of production-line workers. Again, no photos were allowed :-/ I'm not good at estimating numbers of people, but I'd guess that there were perhaps 50 new hires being trained at that time. (When we asked, Sony said that the training schedule is variable, depending on needs, but that they typically train a new batch of workers every 3-6 months.) What we saw was the "classroom" training, before workers go onto the line. It takes two weeks to train each worker; one week in the classroom, and another week paired with an experienced worker on the production line itself.

The training was interesting; there were three parts to it. First was learning how to put tiny screws into tiny holes, over and over again. The repetition involved to train the workers for this was frankly mind-numbing to contemplate. These screws were tiny: Look over your camera to find the smallest screws visible on the outside. There are screws inside that are even smaller. Each block must have had 300 or so threaded holes on it that the workers needed to fill one after another, as quickly as possible. A trainer walked up and down the rows of prospective workers, with a stopwatch and clipboard in hand, stopping from time to time to comment to one or another of the trainees. I don't know how many days they spent putting crazy-tiny screws into crazy-tiny little holes, but doing so is one of the most fundamental tasks on the assembly line, so they need to be able to do it fast and accurately.

As mentioned earlier, if they can't come up to speed after the screw-driving training, they're given a chance to repeat that part of the course. Even at that, about 30% of recruits wash out at this step. After the screwdriver training, the trainees split into two groups, one learning soldering, the other practicing inserting delicate flex-circuits into connectors. Once each group has finished with their segment, they swap to practice the other task. All workers go through classroom training on all three skills.

As you might expect, given how densely packed things are inside cameras, soldering involves itty-bitty wires and other components. I expect there are other, more advanced tasks that are trained for as well, but when we were there, the workers were all learning how to get the right amount of solder on tiny pads, with proper wetting. (That just means that the solder melted and flowed to cover all of the pad. If it doesn't do that, there's a chance you might have a "cold" solder joint, meaning that the solder isn't actually bonded to the pad or component, so can come loose down the road, due to vibration, temperature cycling, etc.)

Here, the practice elements were circuit boards maybe 3 x 5 inches or so in size, with what had to be a thousand or more tiny pads on them. Soldering iron and fine solder in hand, the worker would move from one pad to the next as rapidly as possible, depositing just the right amount of solder and making sure it was a good joint.

The last part of the classroom training we saw was flex-circuit insertion. Here, the trainees had little circuit boards (again, in the general size range of 3 x 5 inches), this time with a dozen or more connectors of different sizes on them. They had little bins of flex-circuit stubs (just an inch or two long) that they'd pick up with tweezers and insert into the variously-sized connectors. This looked to me to be the most challenging task. The flex-circuits are, uh, flexible. So it takes a fair bit of skill to handle them with tweezers and get them fully-seated into the connectors without the flexible material buckling. (I know, I've tried it when repairing or upgrading my laptops sometimes.) As with everything else, they practiced over and over, always working against the clock.

In the training area as well as the rest of the factory, I was impressed with the work ethic. It's possible things were quieter because they knew they had VIP guests touring, but these people *crank* it! No talking or shooting the breeze with their neighbors on the line; it looked like total concentration. The operation was also smooth. Thinking about it, this has been a characteristic of every camera or lens production line I've toured to date, and it makes sense. There's no hiccups or drama, just focused attention and a steady flow of parts and products from one station to the next. There's testing and checks at virtually every stage of the process, too, so any problems that do occur aren't propagated further down the line.

Summary

I've seen enough production facilities now that it's easy to become blasé about the speed and precision. It's really impressive to pause for a moment and look at it with fresh eyes again, though. Modern cameras are an incredibly complex melding of sensors, analog electronics, processing circuitry and mechanical parts. Each one is a small miracle in its own right, and factories like Sony's Chonburi plant crank them out by the thousands, with very, very low problem or failure rates.

While I don't have the illustrations to explain or the memory to recall all the details, it was clear from both the morning presentation and tour of the production lines themselves that quality control and process improvement are at the very core of the Chonburi plant. The production database must absorb millions or tens of millions of data points every day, representing tests and checks at virtually every process step in the factory. Big-data software then lets the QC and production-management specialists comb through it all, looking for small trends or drifts in specs. The goal is to find and correct a drift before the part or process gets out of spec, and to maintain ever-tighter control and tolerances across the entire system. If something does go wrong, they can trace the problem back to its origin. (Something always goes wrong; Murphy's Law applies in Thailand, too :-)

All in all, it was a very impressive demonstration of production prowess, which was obviously the point of the whole trip for Sony. Thailand in general and Bangkok in particular were also fascinating places that I'd like to return to, particularly given how much time I spent stuck in the hotel room doing non-trip work :-/

Thanks to Sony for being such fantastic hosts, and for sharing some of what goes into making one of our favorite cameras. (The A7R Mark II is a truly amazing product: It won our Camera of the Year award in 2015.)

• • •

Local color: A night out and about in Bangkok

While the factory tour was the main focus of the trip, Sony also treated us to a bit of Thai culture in the process. Here are some shots from our second night in Bangkok, featuring a visit to Bangkok's huge and bustling Chinatown.

Bangkok has some spectacular architecture and unique spaces. This open-air restaurant was on the 52nd-floor level of a 70+ story skyscraper. It was pretty windy at that altitude, but the design of the space and surrounding walls blocked all but the mildest of breezes. You can't tell in this still shot, but the clouds you see around the moon were just racing past. Can you recognize any of your favorite photo editors in this shot? :-)

As noted, we went for a little walkabout of Bangkok's Chinatown area after dinner. Established in 1872, it's one of the oldest Chinatowns in the world, although that probably has little relevance to how it looks today. It's certainly big and bustling, though. At night, it's mobbed with people sampling the wares of hundreds (thousands?) of little street stalls, offering a variety of food. This is a look down a main thoroughfare, giving you some idea of its extent and the number of people there.

There were lots (and lots and lots) of piles of fresh food, some of it more appetizing in its uncooked state than others. I wonder how many tons of ice the Chinatown street vendors go through on an average night, keeping their raw materials cold and fresh? It's hard to convey just how many food stands there are!

There was a lot of seafood on display; jumbo prawns seemed particularly popular.

Squid and octopus were big sellers; this kind of roasting over open coals was quite common. I had the feeling some of the presentation was aimed at drawing in tourists looking for a thrill. On the other hand, I'm a particular fan of squid tentacles myself, so they may just be catering to local demand.

I didn't get a chance to sample many of the offerings, since we'd just had dinner, and the group was moving through the market at a pretty steady pace. I want to come back to Thailand on my own sometime, with more opportunity to be a tourist. (I ended up missing out on a lot this trip, because of work that piled up on me from Stateside.) This Chinatown food is enticing, but I'm really wanting to check out the phenomenal Thai street food, as my friend Gordon Liang did. I'll be sure to look up his article, whenever I have a chance to go back.

It's got to be hard work, being a Bangkok street vendor. Get up early to get the food and supplies, schlep everything to your patch of pavement and set up, serve passers-by for hours, then knock it all down, haul it off to wherever you keep it stowed, and then do it all over again the next day. A lifetime insomniac, I envied this woman her ability to drop off for a nap in the middle of the chaos of Bangkok Chinatown at night. (On the other hand, if I had to run a Chinatown street-food business, I'd probably be ready to nap at a moment's notice as well.)

Another shot looking down on one of the main drags. Bangkok traffic is legendary; cars, tuk-tuks (see below), motor scooters and bicycles compete for every square inch of pavement. It does move eventually, but at its peak, it can take an hour just to move a couple of miles.

Bangkok does have a pretty decent mass-transit system, but it lacks the clocklike precision of Japan's. It took a bit of adjustment on my one outing on my own there, as two weeks in Japan prior to Thailand had me accustomed to just hopping on the train that showed up when Google Maps said it should. The different transit lines are also much more clearly marked in Japan. (Or maybe I just wasn't picking up on the visual cues in Bangkok.) In any event, I soon learned that I had to pay a lot more attention to the train numbers than their arrival/departure times. I would have caught on quicker if I wasn't so fuzzy-headed from a couple of weeks of sleep deprivation, but I had quite the "scenic tour", as I jumped on a train arriving/departing at the designated time, only to discover it was an entirely different line than the one I had intended ... then doing that immediately again, trying to get back to my original route.

Regardless of my misadventures, Bangkok's mass transit seems pretty functional. It doesn't handle remotely the volume of the Tokyo Metro system, though, so there's lots and lots of people needing to get places using the roads.

I just mentioned tuk-tuks; these are three-wheeled open-air taxis that are ubiquitous in Bangkok. Given Bangkok's climate, which varies between hot, hotter and beastly-hot, tuk-tuks are more interesting for the experience than for getting around on a practical basis. Definitely avoid them during peak traffic times, as you'll be sitting in tropical heat breathing exhaust fumes for hours. Taxis are also actually cheaper for longer trips. I don't have any extensive knowledge myself, but whether tuk-tuk or taxi, you need to pay attention and assert yourself to avoid getting ripped off. Even then, tourists usually end up paying a lot more than locals. Check out this quick guide to hiring taxi or tuk-tuk, if you're planning a trip there.

This young woman was very sweet; she had a street stall selling some sort of squid thing. She offered me a sample, but I was out of Thai Bhat at the time, so said I couldn't pay. She said "no problem, here, taste!" She was just happy for me to have the experience of her food.

Coming to Thailand, I realized that my prior experience of Thai people was mainly limited to staff at Thai restaurants. So they were a naturally self-selected group who were friendly, outgoing, and customer-oriented. Meeting a broader cross-section of Thais in their home country, I found that a lot were in fact very friendly, but others were just people like anywhere else; some friendly, some less so, some polite, some rude, etc.

I'd also just come from spending two weeks in Japan, so shopping for a few minor clothing items in a Bangkok mall was a bit jarring by contrast. In Japan, store clerks are so accommodating they border on obsequious. In department stores there, I've often felt as though it was the clerk's life mission for me to have a perfect experience at their store that day. Not that American store clerks are awful, but shopping in Japan is really a whole different experience.

Speaking from my vast experience of an afternoon's shopping in Bangkok </irony>, the Thai seem quite different. Some store staff were polite and helpful, others were outright rude. It felt more like America, perhaps even with a bit more of an edge.

Maybe it's just that there's more of a range; there were certainly plenty of Thai people I met like the young woman above, who was just so pleased to be able to give me a happy experience of her culture.

I very much want to return to Thailand, but with much more time and less work to stay abreast of. It's a fascinating culture that I just barely skimmed across on this trip.

Here's a closing shot from our next-to-last dinner in Thailand, on the island of Ko Samui. Three young men treated us to an amazing fire-dance performance. I liked this shot because I managed to get the nearly-full moon in the background and the little flame in the foreground that they used to light their batons and torches from.

In this act, the dancer was swinging a large mesh pot of something that was spitting sparks in all directions. It had to be a pretty large mass of material to burn for so long, while so much of it was being sprayed all around; this act must have required quite a bit of strength. It was certainly a spectacular effect!

Thanks to our hosts!

It was a fascinating trip, from start to finish. Anyone who knows me knows how much I enjoy factory tours and the chance to talk with camera and lens engineers. Getting to see Thailand for the first time was icing on the cake. Thanks to everyone at Sony and to our Thai hosts for such a great experience!