Sony Kumamoto Earthquake - first public footage, DEVASTATING!

posted Thursday, August 10, 2017 at 9:29 AM EST

In April of 2016, a 7.0 magnitude earthquake struck Kumamoto, Japan, the home of the Sony factory that makes a majority of the image sensor chips for the camera industry. Only 20 kilometers from the epicenter of the shallow, violent quake, the impact on the factory was devastating, but I don't think any of us realized just how devastating it was until now.

Along with a very small group of other photo-industry journalists, I was given a tour of Sony's Kumamoto sensor factory just yesterday. As part of the tour, we were shown a video of quake, the almost unbelievable damage to the factory that resulted, and the herculean efforts by the Sony factory workers to restore operations.

Here's that video:

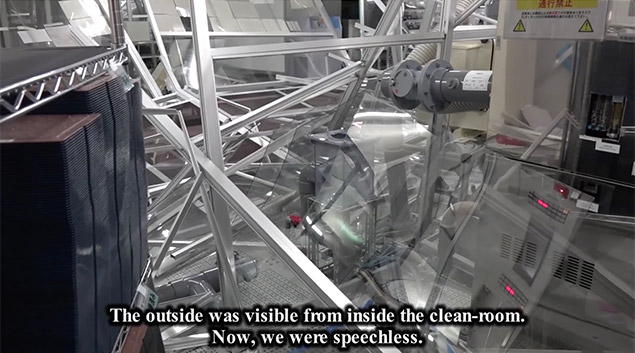

When I first heard of it, I imagined machines getting jostled off their moorings, and maybe some of the special localized clean-room areas breached, etc. Instead, machines were on the ground, all the wafers smashed to bits, ceilings caved in, major structural damage, and places where what was once a clean room was open to the sky above!

Watching the video, I was utterly amazed that they managed to get the plant operating at any level as quickly as they did, and the fact that they were back to 100% capacity by November of the same year is equally astonishing.

Keep in mind the level of cleanliness they needed to restore the clean rooms to: The large areas of the facility, traversed by the human maintenance and support staff (the factory is almost entirely automated) are Class 1000 clean rooms. That means that there are less than 1,000 dust particles of 0.5 microns or larger in a cubic foot of air. That's pretty "dirty" by clean room standards, but it's 1,000 times more pure than typical room air. That's not where the action happens within a semiconductor production plant, though. The silicon wafers themselves and the machines that deal with them are never exposed to more than Class 1 conditions, which means no more than one dust particle 0.5 microns or larger per cubic foot of air. That's seriously clean! But even those environments were breached and exposed room air. And not just normal room air, but the dust and debris-filled air after the ceilings had come crashing down in a major earthquake.

Because Sony owns something like 70% of the camera sensor market, the Kumamoto quake put most of the camera industry up to a year behind, in both product shipments and the release of new models. Fortunately, the factory is now back up to full capacity, churning out sensors 24/7.

We (and a few others) will have more coverage of our time in Kumamoto and with Sony execs before and afterwards. But this video was so dramatic, I wanted to get it posted for our readers without any delay :-)

Stay tuned for more, but meanwhile, ponder for a moment the enormous effort expended by a few thousand people in Southern Japan, to get their sensor fab back online so you can have your new latest-and-greatest camera!