Q&A with Sigma CEO Kazuto Yamaki: Geeking out over industry firsts in camera lens tech and testing

posted Friday, September 21, 2012 at 4:27 PM EST

IR's Dave Etchells totally geeked out over Sigma's announcements at Photokina 2012, calling many of them firsts for the camera industry. And we're not only talking about their new products, but also their ground-breaking approach to quality control and lens development. Sigma CEO Kazuto Yamaki sat down with Dave to share more details about his company's exciting news and future direction.

Dave Etchells/Imaging Resource: Let's start off with a question about business climate from one of our editors. How has the outlook changed since our last interview at CES? Is Europe looking any better? And last time, you said that it looked like the U.S. market was picking up, is that still the case?

Kazuto Yamaki/Sigma: It's still the case, yes. The U.S. is picking up, but Europe is not doing well.

DE: We are seeing a lot of momentum with mirrorless or compact system cameras in general, and we are excited to see you continue to release great lenses for those mounts. There is an interview with someone from Sigma China a little while back that got a lot of coverage when the representative was reported to say that Sigma had no plans for its own mirrorless camera system. Can you confirm whether that is true?

KY: Currently, we're not planning to make a mirrorless camera, because we're prioritizing support for existing systems, our SD and DP cameras. We have to take care of our existing customers. But that doesn't mean that Sigma will never make compact system cameras in the future. Right now, it is true that we don't have any plans to do so.

DE: How is the SD1 Merrill edition selling since you made the dramatic price reduction?

KY: It's been well received, because some potential customers couldn't afford the original SD1. So after the price adjustment, it has been well received by customers. And also to those customers who purchased the original SD1, we offered them a support program where we gave them points which were equivalent to US$4,000 as compensation for the price gap. And these customers could buy our products with that credit.

DE: That was a great solution. It was a potentially difficult situation, but I think Sigma handled it well, you took care of your customers. How are the Sigma fixed lens cameras, the DP series, doing? They seemed to be priced very competitively compared with some other large sensor cameras on the market.

KY: They're being extremely really well received among the Japanese photo enthusiasts. We've had a great success. And the sales in America are also picking up. Customers seem to be quite happy with the performance, because it is easier for them to take really great photos. There's less camera shake because there's no flipping mirror, and no loud focal plane shutter -- the lens shutter is much quieter. So handheld photos are easier with those cameras. And also, in every single DP camera, we align the image sensor, the image plane to the optical axis. So in theory, these compact cameras can offer perfect images.

DE: Speaking of lenses, we are curious about your decision to do away with the EX and non-EX categories in favor of your new scheme with Contemporary, Art, and Sports. What contributed to your decision to do that?

KY: First of all, regarding the EX branding, that kind of concept worked several years ago. But these days, cameras are much further developed. Every year, DSLRs and compact system cameras have more pixels and higher resolution. So the newer lenses always have to be better than the older ones. Now a new non-EX lens might be better than an older EX lens.

We felt that the old approach might confuse customers, so we decided not to risk that. Instead, we wanted to clarify the approach we take in designing lenses. I have always worked very closely with the engineers. And obviously, the product development is a matter of a trade-off. You can't expect the perfect lens -- the best optical performance, the perfect image and an extremely compact size. So it is a matter of which of these we should prioritize. If we prioritize image quality or optical performance, we have to compromise the size and the weight -- it gets bulkier naturally. If we prioritize the compactness, we have to compromise with distortion or vignetting a little bit.

By offering the new product lines, we want to clarify the product concepts, the approach that we take in designing lenses. Our objective is not to impose a specific usage of the lenses, but to clarify our product lineup.

DE: So you want to make more evident to customers what the tradeoffs are in those lenses.

KY: Yes, and also our product concept, because this year has been a remarkable year for cameras. We see super high-resolution cameras, super high-performance cameras, some with less pixels, and we saw very compact cameras. A lot of diversification has started this year. Until last year, every camera had more pixels and tried to be faster, but now, it's clear that there is no perfect camera. Naturally, if they have more pixels, they get slower in reading out the image data and processing the image.

I think in the coming year, this kind of diversification will happen more and more. And for lenses, it is not so clearly delineated. With these new product lines, we'd like to offer lenses for these diversified cameras.

DE: Will that new categorization be applied retroactively to all of your current product line, or will this just be applied to new models going forward?

KY: Just the new models.

DE: And by the Sport designation, should we think of fast action sports photography, or sport as in more durable, able to withstand more abuse?

KY: Again, we aren't imposing a certain lens usage. So with the concept of Sports, we're just clarifying the approach we have taken in designing the lens. But naturally, they can still use a sports lens for portraits and things like that. But we assume that the customers mainly use them for sports, or wildlife, or aircraft, things like that.

For those purposes, all of the Sports line will have weather sealing. And also in the sport lines, we provide some customization functions in conjunction with software.

For example, the customer can change the focus limiter settings. So if they take pictures of, say, aircraft, they might want to limit the focus limiter very close to infinity; and they can do that. But for us, as a lens manufacturer, we have to balance many customers' needs. We offer a different setting as a default to satisfy the majority of customers. But for those customers who have special needs, they may want to change the setting, so sport lenses will offer these customization functions.

DE: So this is really an electronic focus limiter. Traditionally on long zooms, you'd have a focus limit switch or something, or macro lenses where you could lock out the macro range. But this is a way to do that electronically now.

KY: The lens still has a focus limiter switch, but we do it electronically.

DE: Basically, the switch just engages the focus limit. It enables it. And then it will work to whatever limit you have set for it.

KY: The new lens has a focus limiter switch, which works for default setting. And there is another customization switch. If the customer changes that setting with the USB dock, by turning on the customization switch, the lens switches to the customization mode. If they switch back, the camera goes back to the default setting. So customers can choose a setting in the field.

DE: I have been thinking maybe I want to photograph aircraft, but then later in the day, I want to use the lens more normally -- you can have the default as well. To sum it up, you can have no focus limit, default focus limit or custom focus limit.

KY: Yes.

DE: That is really a first for the industry. The first S lens, the 120-300mm f/2.8 DG OS HSM, has better build quality in the weather sealing. Based on what you just said, we could expect to see other Sigma Sport lenses that have similar build and weather-sealing characteristics.

Now the 17-70mm f/2.8-4 DC OS Macro is your first Contemporary model, and it is the third version of that lens now for you. It's lighter and smaller. How were you able to achieve that?

KY: There were several techniques we used. First of all, we used a new material that we call TSC: Thermally Stable Composite. It helps to make it compact. And also, we used a different lens structure.

DE: So a different lens formula internally, and mechanically. The structure is different.

KY: Yes. From the beginning, the optical engineers and the mechanical engineers worked closely together to make it compact.

DE: We talked about the USB dock on the Sport lenses, where you can change the focus limit. Other than that, is its main use to adjust the front or back focus of the lens that matches your body?

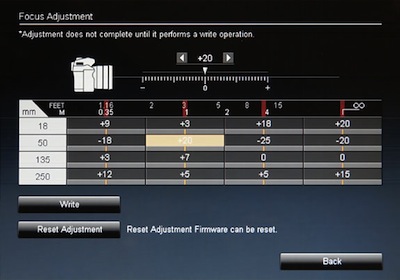

KY: Yes, it's like a micro-adjustment in the body. But for in-body micro-adjustment, you can only change the focus correction for the entire focusing range. If you are happy with the focus accuracy at infinity, but you are not happy with it at three meters, when you change the settings for three meters then you are off at infinity. The focus position for the lens is not linear. With this software, customers can choose a specific focus distance at which to shift the focus position.

DE: And you can adjust multiple focus distances, and basically change the curve.

KY: Yes, and in the case of zoom lenses, photographers can also choose the focal distance.

DE: For the different focal lengths. Wow.

KY: This is just an example, so this is not the real user interface (referring to image at right). They can choose the focal length, and they can also choose the focusing distance.

DE: That's very sophisticated. There is really nothing else like this.

KY: Micro-adjustment is basically a trial and error technology, so I don't think it's very easy to use. Even micro-adjustment in the camera body, it's not very easy. But we wanted to offer this kind of option to our customers anyway.

DE: You say it's a little bit of trial and error with micro-adjustment. It's kind of the same here, the user will have to decide to make changes… how much to change it. So this will work for any Sigma lenses?

KY: For the new lenses.

DE: To confirm, the new lenses going forward: the three new lenses that were just announced and then any new ones coming.

KY: Yes. Depending on the lens, the customization function available will vary. Sports-type lenses will have more customization functions. For all lenses, customers can change the micro-adjustment that is available. But the focus limiter, some lenses won't have, obviously… So depending on the lenses, there is a difference.

DE: As a certified measurement geek, I'm really interested in your new A1 measuring system. That's probably been one of the most significant announcements in the show for me personally. Did I read the press release correctly to say that 100% of your lens production will be tested on this new system?

KY: Yes, for the new lenses. Even today, we inspect 100% of our lenses by our own dedicated MTF system. For the MTF system, we capture the chart and we analyze the image data by the program and measure the MTF performance. In order to capture that image, we're using a conventional Bayer-filtered image sensor. We realized that in order to offer better optics to support the higher-resolution cameras like the D800 or our own SD1, the MTF system needed to have a higher resolution, a higher spatial frequency.

So we needed a better sensor for the system. But when we were in planning, we couldn't find a suitable sensor in the market. But eventually we realized: "Wait, we have a higher resolution sensor -- ours." Of course, we decided to use that. And also, we created a new chart for ourselves. We invented it just for this system, and we developed the algorithm, we developed the program, we did everything ourselves.

DE: Does it give you a two-dimensional look at the sharpness or MTF? Is it just a single point or is it looking at multiple points to calculate MTF? When you're measuring the MTF with the lens, are you just measuring it at the center or multiple points?

KY: Multiple, of course. The center and the corners.

DE: Sample variation is always a problem for every lens manufacturer -- the difference from one copy to the next copy and so on. Do you think that this system will reduce sample variation for you then?

KY: That's one of the goals. A long time ago, we inspected all our lenses with projection; that was normal in the industry. And we let the human eye decide which is a good lens, and which is not. It was dependent on human judgment. Now with the MTF, we can get really objective measurements.

DE: And does the system look at other parameters besides just MTF? Or if you've got the MTF where it needs to be, then everything else kind of falls into place, you know: the chromatic aberration and that sort of thing.

KY: Chromatic aberration, distortion, vignetting, those kinds of issues don't change from unit to unit. It's a design matter, so we do not check them. But I'm very interested in improving and bringing more innovations to this A1 system, because Foveon sensors can capture three colors at each pixel; it's actually a full color image sensor. By doing that, we can measure the camera lens performance in areas other than MTF. We may be able to make other measurements, but we're still researching this.

DE: I find it exciting, because from every lens manufacturer, we see a lot of lenses with centering problems where one element's maybe a little bit off, and then one side will be soft and the other side will be sharp. And when I read about your new system, I thought, "Maybe that's finally the solution, to get MTF data from across multiple points on the focal plane." In my mind, this really throws down the gauntlet to other lens makers to increase their quality control. How long ago did you begin working on the A1 system, and how difficult has it been to implement?

KY: I think we've been working on it for about one and a half years.

DE: And that was building on what you had previously with the old MTF system?

KY: Yes, and it took some years to develop that system. But since we had that experience developing the previous MTF, we were able to do it faster this time.

DE: Videographers are starting to use full frame DSLRS now. But in that situation, focus motor and aperture noise is very important. Do you see that as an opportunity to create lenses specifically for that application, with very quiet focus and that sort of thing?

KY: Yes, but in order to make lenses that are perfect for video, we have to change the optical design.

DE: A good video lens is different from a good still lens.

KY: For manual focus lenses, it's fine. But if we have to support auto focus and a quiet aperture, we have to change the optical design. Because the lens always has to track the subject. In order to do that, we have to make a focusing lens very light and small, because powerful, quiet motors aren't available. But for still imaging, we can use a much heavier, larger focusing lens.

DE: It appears that's a market that you're certainly looking at, but it involves reconfiguring the optical formula to the lenses.

KY: Yes.

DE: You previously mentioned that you're now using Thermally Stable Composite in your lenses. How does that differ from polycarbonate? And is it more expensive to manufacture than polycarbonate?

KY: TSC is more expensive than normal polycarbonate. The important difference is in its thermal characteristics. Actually, polycarbonate is very good in terms of molding accuracy. From unit to unit, the differences are very small once we make a good mold. For metal, we have to process the parts with metal milling machines. There, the tools wear, they don't stay the same. That affects the accuracy.

Plastic is better in terms of accuracy. But the problem is it's very thermally dependent.

DE: It has a high coefficient of expansion?

KY: Yes. The characteristics of TSC are very similar to aluminum. It lets us combine the advantages of both plastic and metal -- it is very stable in accuracy, and also very stable thermally.

DE: I really appreciate you for speaking with us here at Photokina 2012. As always, it's been a very illuminating interview. Thanks again, and we'll see you at the next show!

KY: Thank you very much.