The end of onion-ring bokeh? Panasonic beats the curse of aspheric lenses

posted Friday, May 2, 2014 at 11:50 AM EDT

No free lunch?

Aspheric lenses meant onion-ring bokeh... until now.

Aspheric lens technology is part of the reason many modern photographic lenses are better in so many respects to models from 50 years ago. Lenses with aspheric elements inside have less spherical aberration and are considerably smaller than similar ones designed without aspherics.

As they say, though, there's no free lunch, and modern aspherics have brought along issues of their own, including something called "onion-ring bokeh".

Until now, onion-ring bokeh has been a more or less unavoidable consequence of using aspherics in certain parts of lens designs, but I learned on a visit to their main Yamagata lens factory in mid-February of 2014 that Panasonic has apparently beaten this problem. There, I met with Hirotsugu Yabuta, Director, Optical Devices Business Unit (the manager of the Yamagata factory), Kazutake Boku, Manager, DSC Business Division (Panasonic's head lens designer), and Koji Fujita, Imaging Team, Communication Group, Overseas Consumer Marketing Center (a member of their global marketing team, who served as translator, facilitator, and general ombudsman for my visit).

Without further ado, let's look at the story of aspheric lens elements, onion-ring bokeh, and the extent to which Panasonic has managed to beat it.

What is bokeh?

Isolating a subject by blurring the background and foreground is a very common photographic technique, helping to focus the viewers attention by removing distracting detail behind or in front of the subject. This works great if the blurred background has a nice smooth and creamy look to it, but if background elements are rendered poorly, that rendering can itself call undue attention to them and interfere with your enjoyment of the image.

The way a lens renders out of focus objects is commonly referred to as bokeh. Bokeh (pronounced "BOH-kay", the "kay" part pronounced slightly chopped-off; short like "eh" in English, but with a bit of an "ay" sound to it) was derived from the Japanese word boke (暈け or ボケ), which means "blur" or "haze." At least among amateur photographers, bokeh was once a largely Japanese concern, an obscure thing that the Japanese photo dilettantes worried about, but that most amateurs here in the US were hardly aware of. As photographers have become more sophisticated and learned from each other over the Internet though, more and more people have come to appreciate the blessings of beautiful bokeh.

What does bad bokeh look like?

Bokeh can go bad in a lot of different ways, and to widely varying degrees. You can end up with strange doubled lines, odd-shaped blur circles, hard edges, or even colored fringes around objects or colored rings around highlights, and the effect can range from mild to severe. The example above shows one type, so-called "Nisen" bokeh. Basically, any time you see anything other than smooth, creamy-looking (for lack of a better word) blurring of foreground or background objects, that's bad bokeh.

What is onion-ring bokeh?

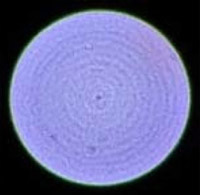

One of the more pernicious forms of bokeh is so-called onion-ring bokeh. As the name suggests, the appearance is that of a spiral or series of concentric rings in out of focus highlights.

If you know a bit about optics (well, OK, maybe a fair bit), it's not too difficult to imagine how some kinds of bokeh arise, but what on earth is going on with onion-ring? What optical process or aberration could possibly produce a pattern like that?

As it turns out, onion-ring bokeh is the result of modern Precision Molded Optics (PMO) technology, a technique used to make aspheric lens elements. To understand onion-ring bokeh, then, we need to look at how aspheric lenses are made.

How to make an aspheric lens

Molded aspheric lenses have been one of photography's great technological developments of the last few decades, bringing dramatically improved lens performance at affordable prices. Aspheric lens elements help reduce spherical aberration and other optical problems in complex lenses, and let lens designers create better lenses with fewer elements.

Previously, aspheric lenses could only be created by a very exacting, time-intensive grinding process, that was ill-suited to mass production. As you might expect, this made aspheric lens elements extremely expensive. Because they were formed by a grinding/polishing operation, it was also difficult to make aspheric elements from high refractive index glass, which is generally much harder than conventional glass, and so would wear down the grinding tools quickly. Aspheric lens elements were first brought to practical use by Nikon, in 1968. (According to Nikon, at least.) Aspheric lenses became more common in the 1980s, but grinding was the rule of the day until 1993, when Nikon released their 18mm f/2.8D prime lens. (Again, this is based on Nikon's information in the link above; I welcome any correcting information readers might have, via the comments section below.)

Currently, aspheric lenses are most often made through a process called Precision Glass Molding or PGM, the results being called Precision Molded Optics, as mentioned above. With this approach, a high-precision mold is made of a very high-temperature alloy, with the desired lens profile carved into it in reverse. A rough-ground lens blank is then sandwiched with the mold and clamped under pressure, and the assembly run through through a carefully controlled sequence of high temperature heat treatments that soften the glass, allow it to conform to the shape of the mold, and then gradually bring it back down to room temperature.

Since the heated and therefore softened glass ends up replicating every last detail of the mold's surface, it's important that the mold have a shape as close to perfection as possible. The critical issue is thus how the molds themselves are created, and what artifacts that process leaves behind.

These days, most aspheric lens molds are created using a process called Single-Point Diamond Turning (SPDT), where a minute, incredibly sharp diamond tool is used to turn the desired profile on a nano-precision lathe. While SPDT can generate very precise profiles, the machines used to do this turning have a finite mechanical resolution, so the profiles generated will have very tiny steps in them. As the diamond cutting tool advances across the mold surface, these minute steps form either a spiral or a series concentric rings. Depending on where the aspheric element is in the optical formula of the lens as a whole, this spiral/ring surface pattern can cause the characteristic appearance of onion-ring bokeh. Basically, you're seeing an image of the sub-microscopic ridges on the surface of the aspheric element.

How big are these tiny rings or ridges? While I unfortunately can't share a copy of the image, Panasonic showed me a roughness profile of a mold made using only "stock" SPDT, and if I'm recalling correctly, the peak to valley distance in the graph was less than 100 nanometers (90nm is the size of an HIV virus, 80nm about a 1/6 of the wavelength of green light)

The concentric rings and surface roughness left behind by the diamond cutting tool in the SPDT process is what produces onion-ring bokeh, another example of which is shown below right.

While they were deliberately a little mysterious about exactly how it was accomplished (and asked me to do the same ;-), Panasonic has found a solution to this problem. The level of precision they've achieved in pursuit of this goal is astonishing: At the end of their production process, the final molds have a total peak-to-valley roughness of just 20 nanometers. That's smaller than the smallest viruses, and only about 1/25 the wavelength of green light.

This is a process they developed over the course of about two years, but one I unfortunately have very few images to illustrate, given its proprietary nature. One stage of the process involves manual polishing of the molds. The small image inset right shows a mold being polished by a worker, which gives you a general idea what the setup looks like.

Panasonic was careful to say that this polishing step was only part of the complete process, and that other parts of the process are responsible for much of the reduction they've achieved in onion-ring bokeh, but I found the manual polishing step fascinating, nonetheless.

Prior to polishing, the shape of the mold is measured very precisely, producing a surface profile plot of the sort I mentioned earlier. The process from there was deliberately left a little vague by the Panasonic factory manager giving the tour (Mr Yabuta), but the general approach is that a computer analyzes the profile plot and spits out a map-like representation of the mold, showing how many "hits" of polishing are needed in what locations to produce the desired smoothing and shape adjustment.

The mold blank is then mounted on a spindle and rotated while a worker applies a small white pad with nano-fine abrasive on it to the spinning surface. Through long experience, these skilled workers have developed "calibrated fingertips," so their polishing "hits" will consistently remove the same amount of material. From what I saw, a single polishing stage might involve a dozen or more hits to make the necessary correction.

Several cycles of this polishing, combined with other proprietary improvements, result in a mold with the aforementioned 20nm peak to valley roughness.

From there, the mold is cleaned, coated with special extra-tough surface material to help it better withstand the rigors of the lens-molding process (the sputter vapor deposition step in the illustration above), and put into service.

Panasonic's refinements of the mold-making process have resulted in a very significant impact on the bokeh quality of their most recent lenses.

Panasonic provided the illustration above, showing the progress they've made in reducing onion-ring artifacts. The image on the far right shows where they started from, a couple of years ago. After a year of development effort, they reduced the onion ring effect to the extent shown in the center image. Finally, after an additional 6 months of work, they achieved the level seen on the left, a remarkable improvement. The final image on the left is an example of a lens made from a mold with a 20nm peak to valley surface roughness described earlier.

As you can see, there's really no sign of onion-ring bokeh in the final image above. Notably, this image is from the recently-announced Panasonic Leica 42.5mm f/1.2 DG Nocticron lens, so it's an example of what can be expected from Panasonic's advanced mold-making technology when applied to a real-world optic.

I don't know whether this advanced mold-making technology will be used to make new molds for existing lenses or not, but I do think we'll see little sign of onion-ring bokeh in Panasonic's new lens designs, going forward.

What might be even more interesting will be to what extent we'll see less onion-ring bokeh in the industry as a whole. It took Panasonic a bit under two years to develop their advanced mold-making technology, but it's something other makers could certainly develop as well, now that Panasonic has led the way.

What's more likely in the short term, though, is that other camera and lens companies may just purchase aspherical elements from Panasonic for critical applications. Panasonic already produces a huge volume of aspheric lenses for other manufacturers, and the people I interviewed for this article indicated that they would indeed sell aspherics made with this process to others ... for a price. In fact, it's interesting to speculate whether this is already happening or not; the 42.5mm f/1.2 Nocticron is the first Panasonic lens to take full advantage of this technology, but who's to say that other manufacturers aren't already doing so as well? Also, as the illustration above shows, the new technology was developed in two steps, the first taking a year, the second another six months. It wouldn't surprise me if Panasonic has already been supplying lenses of that first year of effort to other makers for a little while now.

Summary: The end of Onion-Ring?

This is all great news for photographers, of course, first for those using Panasonic's (or Olympus's) Micro FourThirds bodies, that can use Panasonic's own lenses. Down the road, I expect it will benefit everyone, as other lens makers develop similar technology (unless portions are patented by Panasonic), and/or as other lens makers buy aspheric elements taking advantage of this tech from Panasonic.

Postscript:

I have more coming from my visit with Panasonic, as well as from my meetings with other camera and lens makers during my visit to Japan. Given the volume, the need to digest hours of conversation into something reasonably concise and coherent, as well as the current press of too-much-to-do here at IR, some of this could be a while coming. Stay tuned, though; if you're a geek like me, I think you'll find it interesting!