Sigma Q&A with Kazuto Yamaki: Why no Micro Four Thirds lenses, and is a full-frame Foveon feasible?

posted Wednesday, November 26, 2014 at 7:09 PM EST

Chief Executive Officer,

Sigma Corp.

Finally, another of my interviews from Photokina sees the light of day!

Profuse apologies to all our readers that we're only just now getting another of my interviews published from the Photokina trade show in Cologne, Germany, back in mid-September. Things are always hectic here at IR, especially in the Fall when new models are announced and become available for testing, but this year has been particularly so, for myself especially. Between the flood of new models announced at Photokina, two separate week-long business trips, and the general demands of running the business, we kind of stalled out after publishing my extensive (and highly technical) interview with Samsung's Jay Kelbley, talking about their new Samsung NX1 flagship camera, and the amazing processor technology it has under the hood.

Fortunately, we've finally found time to post another of my chats with Sigma's CEO Kazuto Yamaki, always a pleasant and informative experience for me. Read on below for some insight into Sigma's recent lens developments, the answer to why they chose to announce two different 150-600mm super tele-zooms at the same time, and other insights about how the realities of lens design couple with market demands to define their product mix and production capabilities.

Dave Etchells/Imaging Resource: As we head into the fourth quarter, how's business? Are things going well?

Kazuto Yamaki/Sigma: Yes, we are very fortunate. Our business is growing. Not steep, but it's growing. Actually the biggest problem that we have is a supply shortage.

DE: Really?

KY: Yes, we have lots of back orders that we can't catch up on.

DE: You can't get the raw materials, or the components? What's the shortage -- is it in glass, or something else?

KY: Actually, we have more orders than our capacity.

DE: So it's not the supplies coming to you, it's just being able to produce so many.

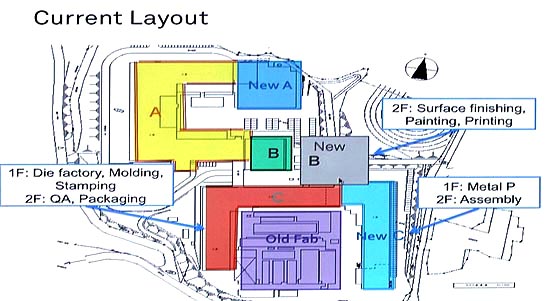

KY: Yes. These last two years, we have massively invested in our company. We increased capacity, especially for lens polishing and processing, but there are two reasons why we can't increase the production volume as much as we'd like. First of all, most of the new Sigma lenses use more glass elements than before, in order to achieve better performance. So in the past we used, let's say, 13 to 14 elements. Now we'll use 17 to 18 elements, sometimes as many as 20 or 21 elements. So for the same lens unit, one piece, in the past we just polished 13 elements...

DE: And now you've got to do 20.

William Brawley/Imaging Resource: The 150-600mm F5-6.3 DG OS HSM | Sport, for example, has 24 elements.

KY: That's one reason. The other reason is, as you know, we do most of the process by ourselves, and we don't use many suppliers. We just use local suppliers; we don't use Chinese or Taiwanese suppliers, so our total capacity is already limited. So we can't increase the capacity in a short time.

DE: Yeah. You can't just flip a switch and increase the capacity. Is it actually the lens polishing machines, or is it the molding machines that are the limit, or some of both?

KY: Actually those were bottlenecks two years ago, but now we've invested so much, lens polishing is not the bottleneck. The bottleneck is assembly. We have a choice to hire many people, but we can't. We are hiring new people, but first of all I'm concerned about the future. Actually, it may be positive, but...

DE: ...you don't want to over-step, yeah.

KY: If I hire too many people, and the market declines more than we can absorb, then we may have to lay people off, but I really don't want to lay people off, so I've been conservative.

[Ed. Note: This is consistent with both Yamaki-san's and his father's philosophy before him, and is a reflection of the attitude that was once almost universal among Japanese companies: They care a great deal about their workers, and the idea of having to lay off workers is almost anathema to them. Recent tough economic times has led to that philosophy being abandoned by most companies, but Sigma still very much maintains it, and extends it to their supplier companies as well. In some cases, as more and more optical manufacturing has been off-shored to other parts of Asia, Sigma has become the only customer for some of their suppliers. Mr. Yamaki has expressed to me on a number of occasions the responsibility he feels towards those companies, their workers and their families.]

WB: You're cautiously optimistic.

KY: Cautiously optimistic, yes. And also, employment is in very high demand in our area because of the earthquake, tsunami, and power plant. So there's lots of construction, and much work for the power plant, to prevent more problems.

DE: So that's absorbed a lot of the workforce up there. That's interesting.

[Ed. Note: Sigma's facilities are located within a couple of hours' drive of the Fukushima Daiichi nuclear power plant, which was badly damaged in the 2011 Tohoku earthquake and resulting tsunami. It seems that the significant labor required to rebuild damaged homes and businesses in the area -- and especially the manpower needed for the continuing effort to contain the situation at Fukushima Daiichi -- have had a knock-on effect on local business' ability to hire workers up in Aizu, where Sigma and some of their key suppliers are located.]

KY: The local people there want to stay in their local area, and the pay there is good. But it's hard to find enough qualified workers.

DE: Wow, that's very interesting. But it's good to hear that there's a positive trend in your sales and production volume.

KY: Yes, we are very fortunate. We appreciate that customers like our products.

DE: Yes, I think in the last few years, with your global vision lenses, people have developed a very different impression of Sigma now; that's neat to see.

I don't have as many questions as usual, and this is kind of a camera question, but a reader wrote in saying that the Quattro is great. How about a full frame Quattro? [laughter] Does the process scale to full frame? Can you make a full frame variant of that chip, or is it just a matter of the market being too small to justify the investment?

KY: I'm afraid I can't comment on specific products in the future, but we've received lots of requests from customers to make a larger-sensored camera.

DE: So you've been hearing that from customers?

KY: Yes, a lot. So we're studying that challenge.

DE: One of our editors also asked about sensor size. Many years ago, there was a 1/1.8"-type Foveon chip. These days, cameras with a 1"-type sensor are quite popular. He's wondering if there's a possibility of going in that direction. Have you heard anything from users on that? Or has it really been just that they want bigger?

KY: Yeah, I think that the 1"-type has an advantage; it's a good size. But in order to provide good image quality with a 1"-type sensor, we would have to shrink the pixel pitch from our current one. Changing the pixel architecture requires a lot of engineering resources and time, so we have to study very carefully before we change the pixel structure.

DE: Ah, that's a whole new engineering process; that's interesting. So going the other direction towards full-frame, you could keep the pitch, and just have more pixels.

KY: That's one option. Of course, we'd have the option to change the pixel pitch in the bigger sensor...

DE: ...to make it bigger, yeah.

KY: But it's easier to keep the pixel pitch, and just increase the die size.

DE: Yeah, interesting. Boy, that would be really high resolution.

WB: That would be!

DE: There would finally be a sensor that could keep up with the 18-35mm F1.8 DC HSM | Art lens, although I guess that's a sub-frame lens anyway.

A reader asked if there's a technical reason why you can't offer your really great APS-C Contemporary and Art-line lenses on Micro Four Thirds with autofocus? I mean, I guess there'd be sort of a size disadvantage, relative to native Micro Four Thirds lenses, because it has a bigger image circle, and it's built for a bigger backfocus. But is that something that you're looking at? Do you hear that request a lot from people, to take some of the existing models and make them in Micro Four Thirds mount?

KY: It's not a big voice, so far. I suppose for some lenses, it's better to make it just for the Micro Four Thirds, for sure. One part of our mission is to provide very good quality lenses, with an affordable price. So in this case, volume is very important. If we share the same lens construction for APS-C and Micro Four Thirds, then we can reduce the cost. If we make the lens just for Micro Four Thirds, possibly the price would be higher. So just by sharing the construction for multiple platforms, we can provide a good quality lens with a lower price.

DE: So that's actually a direction that makes sense for you, to do that.

KY: Yes.

DE: But so far that hasn't been...

WB: The demand for Micro Four Thirds lenses is still fairly low, compared to APS-C or full-frame.

KY: Partly, that's because in the Micro Four Thirds mount, there are already a lot of lenses available.

DE: Oh, that's true.

KY: Customers seem to be fairly happy with the current lineup... On the other hand, for the Sony E-mount, there aren't so many lenses like Micro Four Thirds, so we get lots of requests.

WB: Plus the development of the full-frame E-mount.

DE: Yeah, I guess that's another possibility: You have some very good full frame lenses. It'd be kind of like taking APS-C and translating to Micro Four Thirds, if you take some of your full-frame lenses, and just have an E-mount on them so that they work with the full-frame sensor.

Sigma 2: Yeah, I could see that would be very helpful.

DE: That's been a point with Sony. I think even more so than Panasonic and Olympus, that Sony kind of started out thinking of mirrorless cameras as being cameras for novice users. They felt that the people who would buy their NEX line, back when it was called that, would be people who were stepping up from compacts. So they really focused on cheap zooms and inexpensive lenses, but not with such great quality. Now, they're starting to build better quality lenses, but it's not a very full line yet. I like Sony's mirrorless cameras very much, but the lenses have been an obstacle for many users.

Also, Sony's good quality lenses tend to be very expensive, so there's kind of a price range here, and another price range up here, and there's a huge gap in the middle. That's what I think you're smiling at, because that's where you're like "Yeaaaah!" [laughter]

KY: [grinning] No comment.

DE: Another question from our own staff, one of our technical editors. He's wondering if there's a firmware update or re-chipping service for some of the older Sigma lenses that have problems working on newer bodies. Now I think that both of these, I think I know what it is, and it's not so much a chip issue. This particular editor has a 10-20mm F4-5.6 EX DC HSM lens that won't auto-focus in live view on some of the newer Nikon bodies.

And then in our lab, we use your 70mm f/2.8 DG Macro wherever we can because it's so sharp. So when we're testing cameras, that's pretty much as sharp as a lens can get. But again, our lab tech has found that the 70mm won't auto-focus in live view mode on some cameras. So our editor was asking if there's a chance to update the firmware, or put new chips in them?

But now that I ask the question, I'm also thinking that the problem with live view focusing is that the lens has to be able to move and stop very quickly. The camera has to be able to check focus, and then it has to move and stop again very quickly. So would those issues just be that some lens motors aren't suitable for contrast-detection focusing? Or is it something that could be fixed with the firmware?

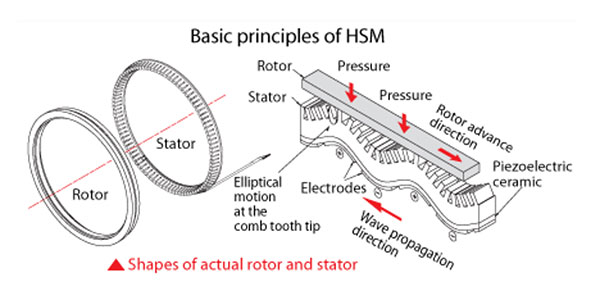

KY: There's two issues. First of all, those lenses are made for still cameras. They're not made for live view autofocus. Live view autofocus is very similar to video usage. But the Hyper Sonic Motor -- or ultrasonic motors in general -- are not very suitable for that kind of purpose. Stepping motors or voice-coil motors are more suitable.

DE: Oh, I see. So ultrasonic maybe isn't able to accelerate very quickly, and stop very quickly.

KY: Yes, right, that's one of the problems, but also the other problem is firmware. Maybe we can optimize the autofocus function for live view mode, so we will continuously improve performance.

DE: So you continue to look at that.

KY: And we will soon release new firmware for our lenses [Ed. Note: This has been released since the interview took place], but just for existing lenses, not for the discontinued models.

DE: Not for the discontinued models, yeah.

KY: The new firmware for some lenses makes them compatible with Canon's Cinema EOS C100 camera. So if the customer has a USB dock, he can upgrade the firmware at home -- or he can send the camera to our office, and then we can upgrade it. So those lenses are now compatible with Canon Cinema EOS. Likewise, we will continuously update firmware [in the future].

DE: The Sigma 70mm f/2.8 EX DG Macro is a current product still, right? Oh... no? That's one that's discontinued. Oh, that's too bad. That was my favorite lens, but not so much demand for it, maybe.

KY: Yeah, that was my favorite lens too. Not so much demand compared to other lenses, though, and also one of the glass materials [used in the lens] was discontinued.

DE: Oh, you can't get the glass from the glass manufacturer. That's interesting!

KY: It's a very unique glass material, so they say. So we could not continue the production.

DE: Wow, that's very interesting. I remember when I was talking to your optical engineers, they explained to me about the glass types. And so one of those, it was like way over here or something [gestures], way off the normal path, and they just stopped making it. Oh, that's very interesting. Too bad. That could maybe also explain why the lens was so good, too, that it was using really special glass.

KY: I don't know. I have to ask our lens designers about that.

DE: Yeah. So what do you have currently as a really high quality, very sharp macro? Instead of the 70mm, what's the closest current current lens in your line?

KY: Maybe it's a bit longer, but the 150mm F2.8 EX DG OS HSM APO Macro or APO Macro 180mm F2.8 EX DG OS HSM. That's very good.

DE: Oh, the 180mm, yes. They're very good.

KY: The 105mm F2.8 EX DG OS HSM Macro is also good.

DE: Yeah, that 70mm was really special though. So basically the message on the firmware is that for currently-produced lenses, that you're constantly looking and trying to fix things, if there's an issue with compatibility. You are releasing firmware updates.

KY: Yes.

DE: Another one of our editors noted that we've talked in the past about the possibility of adding a zoom lens to the DP series. I think the answer we received was that it would increase the size of the camera quite a bit. But the DP Quattro cameras have a body that's somewhat bigger already. So now he's asking, given that the body's bigger, how about some sort of a fixed zoom on a Quattro? Or is the prime really just the way to go for image quality?

KY: Yes, he's right. In terms of the size, now the new Quattro body can accept a bigger lens because the camera's designed for you to hold its grip with the right hand, and hold the lens bottom with the left hand.

DE: Yeah, it's a two handed design.

KY: So maybe the Quattro can accept a bigger lens. The other challenge is the quality. We'd have to implement a very high quality zoom lens, so that is still the challenge.

DE: Yeah. The lens has to be able to match the resolution of the sensor, and be good quality.

KY: And especially a standard zoom lens is quite challenging. If it was a wide-angle zoom, that would be good.

DE: If it's wider, it's easier. But the standard range...

KY: ...is very challenging to implement a good quality.

DE: So we're very interested in the 150-600mm lenses that have been announced, and particularly in the fact that there are two models -- the 150-600mm F5-6.3 DG OS HSM | Sport at $2,000, and the 150-600mm F5-6.3 DG OS HSM | Contemporary is... actually, you haven't announced a price for that model. Do we have a ballpark yet on that?

KY: No, we have not said, but it should be significantly lower. So with these lenses, we started this project as a single project.

DE: Oh really?

KY: It is a renewal of our 150-500mm F5-6.3 APO DG OS HSM. First of all, we wanted to extend the focal length to 600mm. We started, I think, two years ago. And I also set the goals for this project -- first to implement better image quality. Especially, we wanted to minimize chromatic aberration, and extend the range to 600mm, maybe. Second was a dustproof and splashproof construction for the high-end customers. The third one was to be relatively compact and lightweight, just like the 150-500 is relatively compact and lightweight. We did not want to compromise any of these conditions, but eventually we realized that it's quite challenging to achieve them without any compromises.

So in the end I decided to split this one single project into two, with the Sports lens maybe bigger, heavier and more expensive, to implement higher image quality, better construction and build quality, many features. And I wanted to implement a lightweight, compact -- but still good quality -- lens within the Contemporary line.

DE: I see. So as you got into it, you realized that to hit all three of those goals was going to make it a very expensive product, and that really, to get the ultimate image quality it was going to have to be heavier.

KY: Actually, there is not so much difference between the two lenses in terms of optical performance. Especially if you look at the center of the frame, there's not so much difference -- maybe you can't see the difference. If you look in the corner at the telephoto end, the Sport lens' lateral chromatic aberration is significantly less than in the Contemporary line, though.

DE: So it's really the lateral CA in the corners that was the primary difference at 600mm.

KY: The optical design is so sensitive; if you really want to minimize that kind of thing, it suddenly gets bulkier and heavier.

DE: You have to have a lot of elements. That's difficult to do.

KY: Yeah.

DE: That's interesting. So they're very similar in terms of the sharpness then, it's just the CA. But the CA's not difficult to correct in software either. I mean, you build a lens profile in Adobe...

KY: Yeah. But still, users like to have a high quality lens, so we want to meet the demand of the customer.

DE: Oh yeah, I understand. I wasn't saying that there's no need for the higher-end lens, but for someone that can't afford it, they can still get very good quality images.

WB: Because some people are willing to trade off a bit of processing, to get a little bit lighter...

DE: Yeah, they're willing to spend some more time after the fact. Another of the same kind of question -- you have the 18-300mm F3.5-6.3 DC MACRO OS HSM | Contemporary lens, it's been announced in Sigma, Nikon, Canon, Sony/Minolta and Pentax mounts. Is there any chance that might come to Sony E-mount or Micro Four Thirds?

KY: No, because it's made for the conventional DSLR. If we made it for the mirrorless or compact system camera, we'd have to change its optical design for focus tracking.

WB: Like you said, those would be live view platforms, so would need a different focus system.

KY: Yeah, it would have to be a stepping motor or voice coil motor.

DE: Oh, good point.

KY: In the case of the mirrorless camera, the focus has to always track the subject, because of the "wobbling" [in the US, we refer to this as "hunting", moving back and forth to determine the point of focus], always moving a little bit. In this case, the focus glass must be very lightweight.

WB: The elements that are moving have to be lightweight enough to move fast.

KY: Yeah, and also there are not many motors which have both strong power and compact size, so the lens element has to be very light.

DE: Very, very light. And so the design of that lens, I mean, that would be a completely different optical design.

KY: Completely different.

DE: Yeah, different optimizations could be more expensive. Or might sacrifice quality.

KY: It cannot be expensive, but it [would have to be] totally changed, a different design and construction. [Ed. Note: And probably either more expensive or more difficult to manufacture, explaining why they didn't go that direction with the 18-300mm.]

DE: Well, that's very interesting. This is more of a comment than anything, but we've been quite impressed with how quickly you iterated and updated the firmware on the Quattro. You know, we encountered an issue, and you corrected that in a very short time...

KY: Actually, most of the changes were bugs, so we should have fixed them before we started shipping. It's a shame.

DE: Do you anticipate, though, once the bugs are fixed, that there will be other firmware updates coming?

KY: Yes. We will continue to develop [the Quattro cameras].

DE: So users may be requesting features, or functions, and you'll be looking into those.

KY: Yeah.

DE: We had a little more detail to talk about on that, but I think we're actually out of time, so we'll need to end it here. Thank you very much.

KY: Thank you very much. It's very fun to talk to you, because you're very technical and very detailed; you have quite unique questions. It's quite different from others.

DE: Oh really? Oh, thanks!